Transformation of an idea into a working model is one of the first processes of product development, and CAD designing services help in this process, whether a new home appliance, a single mechanical component, or a groundbreaking piece of furniture. CAD computer-aided design software helps to model accurately with the assistance of computers before the actual production process.

Professional designers maximize 3D visualization services and computer-aided engineering design software to simplify ideas, identify defects, and minimize errors. Like Cad Crowd, the number one freelance CAD design marketplace, you can hire an experienced freelance CAD professional to deliver quality designs that satisfy project demands with flexibility and affordability.

In the fast-changing landscape of product design, ideas are tangible, effective, and functional in a tangible, effective, and functional manner. Whether you’re developing a groundbreaking consumer gadget, a complex mechanical part, or a custom piece of furniture, transforming your concept into a prototype is a critical step. This is where Computer-Aided Design (CAD) steps in. CAD technology has become an industry norm for translating creative thinking into real-world, three-dimensional reality and into a design and development process to a level never before attainable.

CAD design services, either by a design house or freelance designers, are the key for small businesses and large corporations alike to bridge the gap of trust between the working model and the idea. But how does CAD actually work, and why must designers use it in order to take your idea and turn it into a working prototype? In this article, we will outline the process of product design with CAD, the CAD services you can hire, and how professional design firms and freelancing services can walk you through it.

🚀 Table of contents

- The basics of CAD in product design

- The role of CAD in turning ideas into prototypes

- Why CAD services are important to product design companies

- Freelance CAD services: The flexibility and expertise you need

- How to choose the right CAD design services for your needs

- Conclusion: The future of CAD in product design

- Cad Crowd is here to help

The basics of CAD in product design

CAD stands for computer software used in designing accurate 2D or 3D representations of actual objects. In product design services, CAD software helps model, analyze, and simulate a product’s form, shape, and behavior before actual production. CAD provides the designer with complete control over the process, allowing for quick iterations, detailed modifications, and functional testing in a manner that would be practically impossible with traditional methods.

The elegance of CAD lies in its ability to transition from idea to reality through a series of flexible, precise, and highly detailed steps. These design steps of test, refine, and prototype are all accelerated and streamlined by the application of CAD.

RELATED: How much does NPD cost? Rates & pricing for services at top design companies

The role of CAD in turning ideas into prototypes

Among all the processes involved in developing a creative concept and turning it into an actual product, the concept-to-prototype stage stands out as the most critical. Among the most groundbreaking technologies that designers employ to advance along the way is Computer-Aided Design (CAD). CAD software equips designers with the ability to shift from sketching all the way to fully modeled digital prototypes, detailing, simulating, and eventually printing physical prototypes. Here is a step-by-step explanation of how CAD has an effect.

Conceptualization and design

Every great product starts off as an idea, a good-looking one. But if that idea is to materialize a real, functional product, then it needs to be designed into something much harder. That is where CAD is needed. From the very beginning of the design, CAD enables the product design expert to take their sketch and scribbled notes and bring them into a computer system, where they have a better and clearer understanding of the product. CAD magic software does its trick, where it all comes to life, transforming abstract ideas into something real and visible.

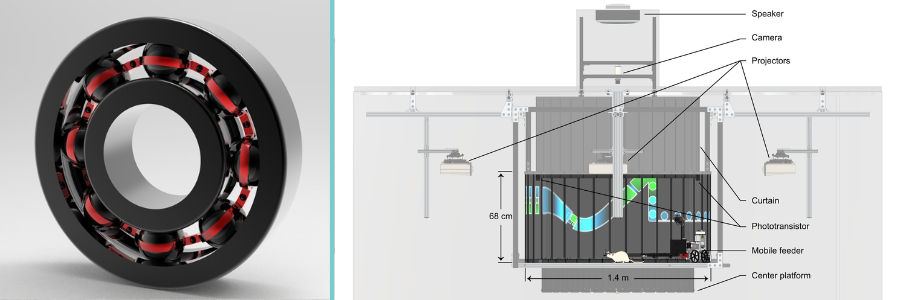

The idea phase is typically initiated by rough shapes, measurements, and forms. For simpler designs, CAD may allow the designer to sketch 2D blueprints that establish the size and overall specifications of the product. They may be similar to blueprints or schematics, containing all the pertinent details like measurements and material usage. But for more complicated designs, 3D modeling is required. A 3D CAD model is a far more realistic and accurate representation of a product, encompassing not only its exterior form but also its internal structure and the interaction of its internal components with each other. A degree of detail such as this is required when designing products with complex functions, such as machines, domestic appliances, or even automobiles.

The advantage of 3D modeling is that one is able to reproduce a replica of the product in the virtual space. This way, one gets to view the product in three dimensions, and their idea becomes concrete in the shape of an interactive digital model. This not only enables designers to see their idea materialize right before their eyes but also gives them the chance to identify any faults in the design and correct them beforehand.

Refining and simulation

Once the initial design is established on CAD, refinement is then performed. The refinement of the design is made easy by the CAD software, which allows the designer to execute it efficiently. Compared to the past, when it could take days or even weeks to make changes to a model, CAD makes it easy to modify computer models with just one click of the mouse button or a maximum of two clicks. With one or more clicks of the mouse buttons, a product design engineering expert can change the shape of a part, resize objects, or change the material.

The most valuable advantage of CAD software is that it enables the simulation of the product’s actual usage. With advanced analysis software such as Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD), designers can plan how a product will function before it is even constructed. For instance, FEA is able to model the strength of a product structure, mimicking how it’s going to disperse stress and pressure. Additionally, CFD also simulates the movement of fluids, such as air or water, within or around the product, allowing for the quantification of the product’s aerodynamic or heat properties.

These tests are time and cost-effective in the sense that they enable potential defects to be detected early in the design process. These, apart from CAD, would include the construction of costly physical models, which could easily translate into costly mistakes where the design proves impractical. CAD is money-saving in the sense that such mistakes can be caught prior to actually doing something physically, thereby saving money as well as delaying things.

Prototyping: Converting virtual models into physical objects

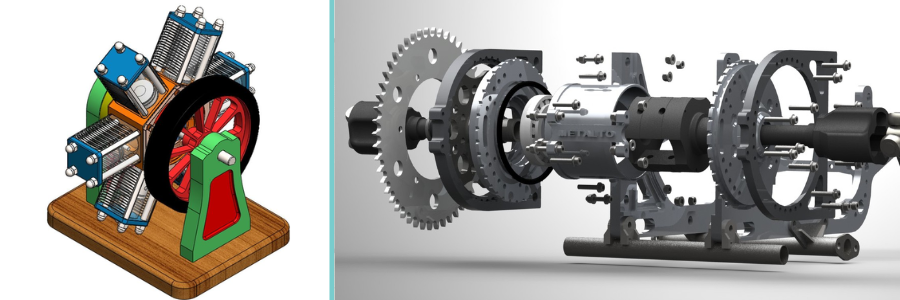

The final and possibly the most exciting part of the CAD design services process is to have the virtual model converted into a physical prototype. Here, the power of CAD is utilized to the fullest. CAD technology is typically used in conjunction with rapid prototyping technologies, such as 3D printing, CNC milling, or injection molding, to produce extremely detailed physical models directly from the computer-aided design. The combination streamlines the prototyping process and speeds up the product development cycle.

The most up-to-date prototyping technology available is 3D printing. In 3D printing, designers may layer-print prototypes in a material similar to that of the final product. That means real-time testing, iteration, and providing the designer with an actual prototype within a specified timeframe if a conventional process is used. 3D printing also boasts better material and design freedom, allowing for the easy printing of complex pieces.

Where there is a need for commercially oriented programs, CNC machining takes up the slack. With CNC equipment capable of milling metals, plastics, and other materials with high accuracy, prototypes are developed that are not only highly accurate but also as robust as any sample that could possibly survive testing under actual conditions. Then comes CNC machining as the issue of most concern to industries like auto or aircraft manufacturing, where models will need to endure harsh tests under harsh conditions.

For production designers, processes like injection molding enable the creation of prototypes that can be produced in large quantities. This is achieved by filling a mold with molten material to create the prototype, and it is extremely convenient when designers wish to see a physical model for assessing the feasibility of mass production.

It is here that the services of a freelancer or CAD design firm can prove to be effective. They can give professional advice on which prototype method would be most effective for the given product above, help in developing accurate 3D models, and help manufacturing design firms prepare the prototype as well.

In product design, taking an idea to a model is a costly and labor-intensive endeavor. CAD technology, however, has changed all that with the ability to offer rich thinking tools for imagining, developing, and bringing one’s ideas to reality in a far more effective and affordable way.

By providing virtual models that emulate actual motion and facilitating integration with future-generation prototyping technology, CAD enables faster and more effective communication of ideas to working models than ever before. As technology continues to evolve on a daily basis, CAD applications in the idea-to-prototype conversion process will become increasingly vital, driving innovation across various industry sectors.

RELATED: How to integrate CAD seamlessly into your firm’s workflow of engineering, design & services

Why CAD services are important to product design companies

For companies, having access to CAD services represents a milestone in product development. The reason why is this:

Smooth development process

CAD services also possess a highly efficient design process. Re-editing, re-drawing, and fine-tuning a design would take time if done using manual drawing processes, but CAD is time-saving when making these changes. Because the person can write, edit, and visualize real-time 3D models, the prototyping design engineering service process is streamlined and accommodates each subsequent copy to be improved.

Accuracy and precision

Accuracy is everything for most businesses, especially those with highly technical or mechanical products. CAD software turns impossible measurements and calculations into reality, ensuring that every component fits together seamlessly and operates as efficiently as possible. Slippage or miscalculation during design can mean costly mistakes down the line, and CAD eliminates these risks.

Cost efficiency

While purchasing CAD services may seem like an enormous initial investment, in reality, it can prove to be a cost-saver for companies in the long run. By identifying mistakes early, improving design before physical prototyping, and reducing product-to-market time, CAD reduces production cost. CAD enables manufacturers to create rapid and low-cost prototypes, saving money again.

Collaboration and communication

CAD enables easy communication with groups regardless of location. Designers, engineers, and product managers can send and receive comments and make changes to a single model, enabling feedback and live editing. For geographically separated or departmentalized organizations, these capabilities can be a godsend for keeping everyone informed.

Freelance CAD services: The flexibility and expertise you need

While major product design companies can retain CAD professionals on their payroll, freelance CAD professionals offer a valuable alternative for small companies or start-ups that need high-quality work without the expense of an in-house team.

Expertise

Freelance CAD designers are experts in their area. If you need help with 3D modeling, prototyping, or simulation, you can hire someone who has the very skill set to bring your idea to life. This will open you up to a pool of talent anywhere in the world, and you can choose a designer who is an expert in your market, automotive, industrial, consumer electronics, or custom furniture.

Economic solution

Freelancers are typically hired on a project-by-project basis, which can be less expensive than hiring an in-house full-time employee or a large CAD design firm. If you will only need CAD work for one project, it is efficient and economical to hire a freelancer. Freelance CAD designers tend to charge competitive fees, which can be beneficial to small organizations with limited budgets.

Flexibility and adaptability

Freelancers offer a level of flexibility that large, traditional corporations simply cannot provide. They can complete your project at your pace, provide more customized effort, and adapt to any changes in specifications during the process. More to the point, they are generally able to come up with more outside-the-box solutions to design issues because they don’t carry the burden of someone laying on them the constraint of having to be outside the box, but rather a very small one.

RELATED: How to create a marketable product design for your new invention idea with design agencies

How to choose the right CAD design services for your needs

Whether you’re working with a CAD design company or a freelance CAD designer, choosing the right service is essential to achieving the best results for consumer product design companies. Here are some factors to consider when selecting a provider:

Experience and portfolio

Seek out a designer or agency that has experience in your industry and a portfolio of their work. You want someone who is familiar with the technical aspects of your product and can design a usable tool that you will need.

Communication skills

Good communication is essential when working with CAD designers. Choose a service provider that responds rapidly to calls, listens, and is able to express intricate design concepts in your frame of mind. Good communication ensures that your idea comes through exactly as you envision it, and you are on the same page throughout the project.

Tools and technologies

Ensure that the CAD vendor you hire is utilizing the latest software and hardware that are standard in their industry. Commercial product design and prototyping are most typically executed with SolidWorks, AutoCAD, and Fusion 360. Also, ensure that they have the capability to interface with rapid prototype technologies such as 3D printing design services or CNC machining.

Cost and timeline

Finally, make the service fit your pocket and time. CAD services are not gratis, but they must be in proportion to your project size and complexity. Finding out how much it costs and choosing an open delivery period before will avoid unpleasant surprises down the line.

Conclusion: The future of CAD in product design

As technology continues to evolve, CAD designing will be the fulcrum around which product designing revolves.

Designing back-and-forth virtually the capability to test and prototype, then to iterate in design at notice, lends itself perfectly well for designers to deliver better products at pennies on the dollar with fewer days’ worth. Whether you’re working with a design company or a freelance CAD professional, the ability to turn your idea into a prototype with CAD is one of the most powerful tools available to product designers today.

With the age of speed for product development experts, CAD’s precision, speed, and accuracy make it the perfect tool for realizing your dream. Whether it is developing the next breakthrough product or a custom piece, employing CAD design services will guarantee that your proof of concept is not an idea, but a functional, tangible piece that can be driven to the development stage.

RELATED: Tips to optimize new invention development and product development for companies

Cad Crowd is here to help

Your idea for a prototype requires accuracy, imagination, and professional expertise.

CAD design transforms pencil-based concept sketches right through to functioning working models of your vision. Freelance CAD design units are able to offer flexibility and expertise at specialist levels to achieve the ideal finish to order, specially crafted to meet your needs.

On Cad Crowd, the best marketplace to find the best product development experts, you can outsource the best freelance professionals to bring your ideas to life in the form of precise, detailed prototypes. Whether you need assistance in end product 3D modeling, end product prototype optimization, or design completion, the right professional will be the difference-maker. Contact us today and start bringing your ideas to life with a free quote.